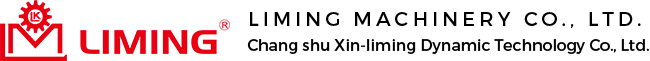

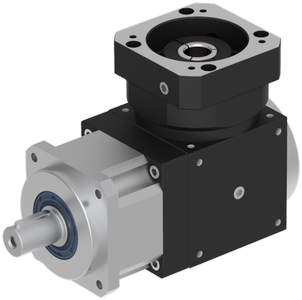

Product Features

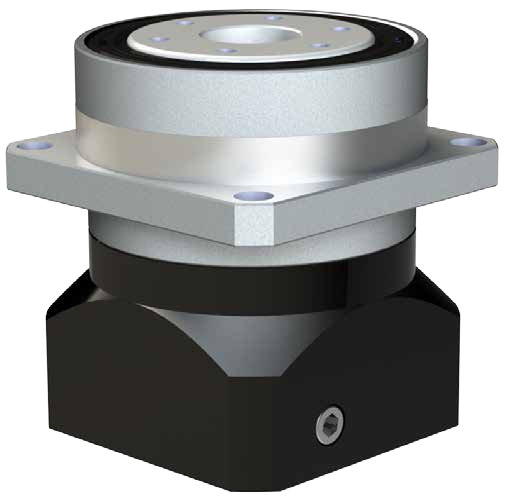

Collet Locking Mechanism:

The input-end and the motor are coupled through a collet locking mechanism. It has passed dynamical balance analysis to assure concentricity and balance on the connection and no backlash for power transmission while running at high speed.

Integrated Planetary Arm Bracket:

The planetary arm bracket and the output shaft are one-piece constructed to increase torsional rigidity and accuracy.

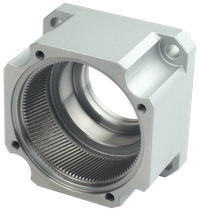

One-piece Helical Gear Box:

The gear box and internal ring gear are one-piece constructed. The speed reduction mechanism employs helical gears, which provides two times meshing rate of teeth when comparing with regular spur gears. In addition, it also has features of extremely smooth running, low noise, high output torque and low backlash.

Full Needle Roller Bearings Design:

The planetary gear transmission employs full needle roller bearings without retainer to increase the contact surface, which greatly upgrades structural rigidity and service life.

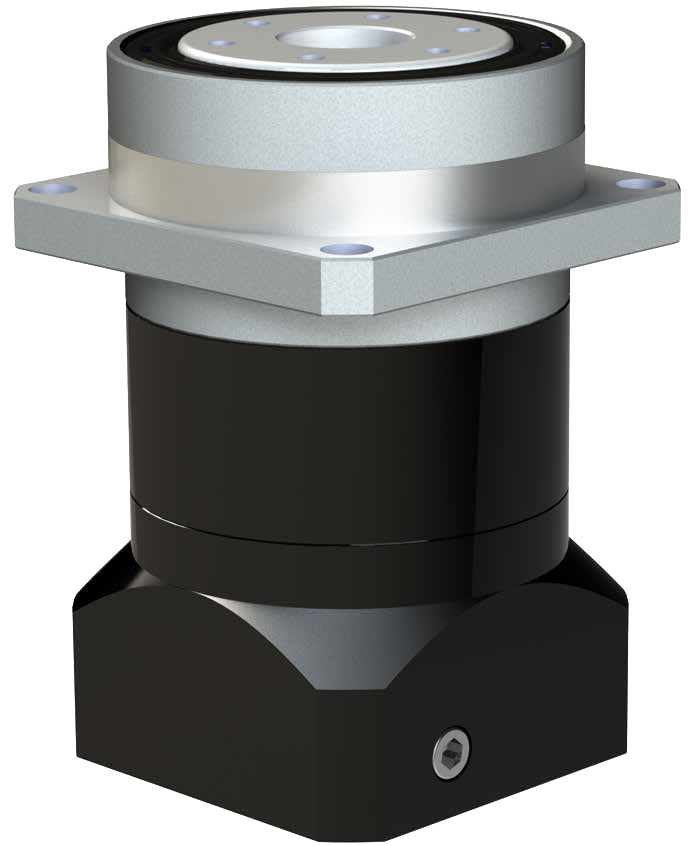

Collet Locking Mechanism:

The input-end and the motor are coupled through a collet locking mechanism. It has passed dynamical balance analysis to assure concentricity and balance on the connection and no backlash for power transmission while running at high speed.

Integrated Planetary Arm Bracket:

The planetary arm bracket and the output shaft are one-piece constructed to increase torsional rigidity and accuracy.

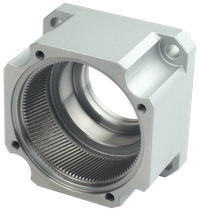

One-piece Helical Gear Box:

The gear box and internal ring gear are one-piece constructed. The speed reduction mechanism employs helical gears, which provides two times meshing rate of teeth when comparing with regular spur gears. In addition, it also has features of extremely smooth running, low noise, high output torque and low backlash.

Full Needle Roller Bearings Design:

The planetary gear transmission employs full needle roller bearings without retainer to increase the contact surface, which greatly upgrades structural rigidity and service life.